Solutions for handling

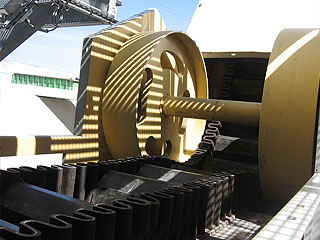

SERA develops, manufactures and installs its own range of systems

specifically adapted to the conveying of wood in all its forms

in the recovery process of the raw material.

The timber control is important to ensure a high availability rate with a heterogeneous matter and uncontaminated by the presence of metal particles, stones, silica and other foreign objects.

What does wood biomass mean ?

Wood biomass represents a set of wood matter such as wood chips, bark, stump waste, composting reject, industry by- products, end-of-life wood etc...

SERA supports you in determining the most suitable conveying equipment for your needs, guaranteeing the homogenization of the heterogeneous matter.