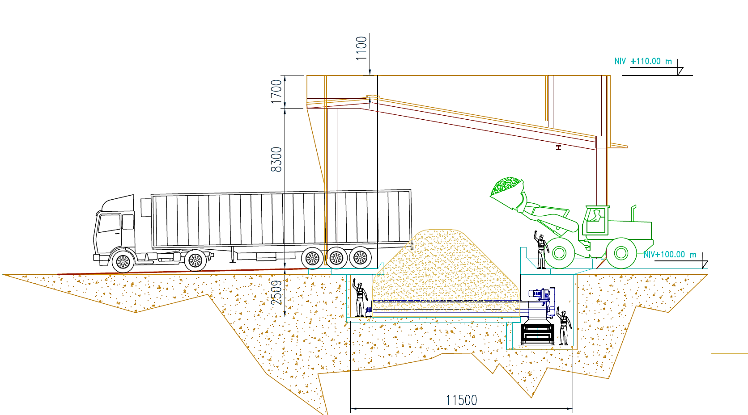

Unloading of biomass and wood chips

SERA has developed a comprehensive range able to meet small boiler rooms' requirement, as well as cogeneration sites for which the number of daily deliveries is significant.

Theexternal feeding of biomass boilers requires that the fuel is delivered by truck to the feeding system of biomass boiler.

SERA also provides various security, dust extraction and cleaning systems, so that the operators' work work complies with health and safety standards.

Fines collected by the dust extraction system are densified so as to be returned to the boiler through the initial circuit. An improved material performance without having to manage dust collected in ATEX zone..